I-High Prescience Water Mist System

Ukuqalisa

Isimiso Sokudla Kwamanzi

I-Water Mist ichazwa ku-NFPA 750 njengesifutho samanzi lapho i-DV0.99, ngokusatshalaliswa kwe-volumetric okugcwele okugcwele kwamaconsi amanzi, kungaphansi kwama-microns ayi-1000 ekucindezelweni okuncane okusebenzayo kwe-nozzle yamanzi. Uhlelo lwamanzi inkungu lusebenza ngokucindezela okuphezulu ukuletha amanzi njengenkungu enhle ye-atomised. Le nkampu iguqulwa ngokushesha ibe umusi oshama umlilo futhi ivimbele okwengeziwe umoya-mpilo ukuthi angakufinyeleli. Ngasikhathi sinye, ukuhwamuka kwakha umphumela omkhulu wokupholisa.

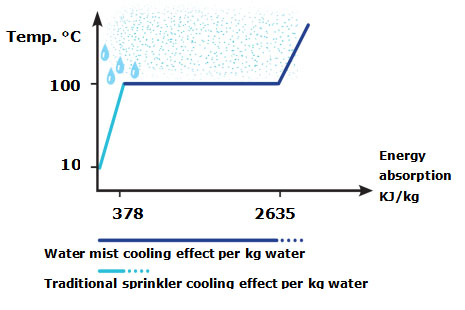

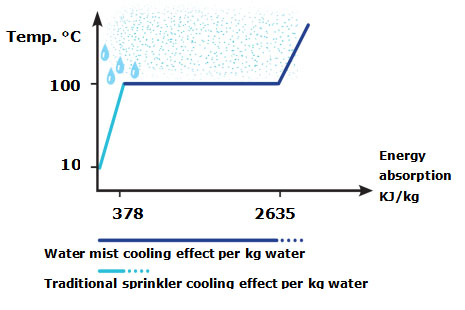

Amanzi anezakhiwo ezinhle kakhulu zokumuncwa kokushisa okuthola ama-378 kJ / kg. futhi 2257 kj / kg. Ukuguqukela kuSteam, kanye ne-1700: Ukunwetshwa okungu-1 ngokwenza kanjalo. Ukuze usebenzise lezi zindawo, indawo engaphezulu kwamaconsi yamanzi kumele ilungiswe futhi isikhathi sayo sokuhamba (ngaphambi kokushaya izindawo eziphakeme) kwandiswe. Ngokwenza kanjalo, ukucindezelwa komlilo kwemililo evutha amalangabi kungatholwa ngokuhlanganiswa kwe

1.Ukushisa okushisa kusuka emlilweni nakuwo uphethiloli

2.Ukuncishiswa komoya-mpilo nge-Steam Scopesting eFlame Front Front

3.Ukuvinjwa kokudluliselwa kokushisa okukhanyayo

4.Ukupholisa kwamagesi wokuhlanganisa

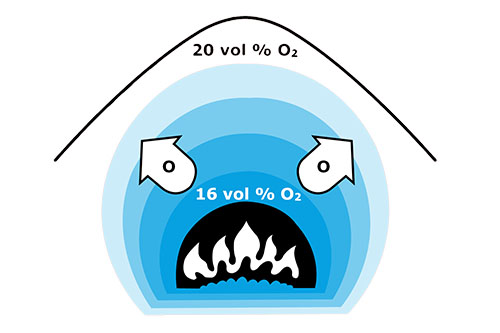

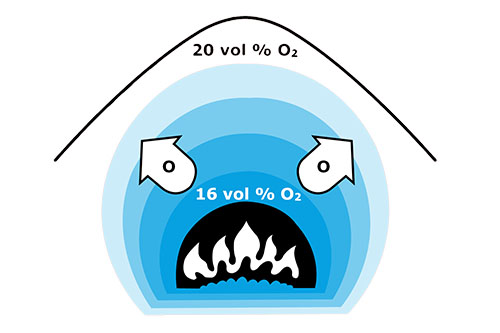

Ngomlilo ukuze usinde, kuncike ekubeni khona kwezinto ezintathu 'zonxantathu womlilo': umoya-mpilo, ukushisa kanye nezinto ezivuthayo. Ukususwa kwanoma iyiphi yalezi zinto kuzocima umlilo. Uhlelo lwe-High-Water Fruscient Am Fruing luyaqhubeka. Ihlasela izinto ezimbili zonxantathu womlilo: umoya-mpilo nokushisa.

Amaconsi amancane kakhulu ohlelweni lwamanzi acindezele kakhulu amunca ngokushesha amandla kangangokuba amaconsi aqhakambisa futhi aguqule kusuka emanzini aqonde emthanjeni, ngenxa yendawo ephezulu yendawo ehlobene nobuningi bamanzi. Lokhu kusho ukuthi i-droplet ngayinye izokwanda cishe izikhathi ezingama-1700, lapho isondelana nezinto ezivuthayo, lapho umoya-mpilo kanye nezinsimbi ezivuthayo zizosuswa emlilweni, okusho ukuthi inqubo yokuhlanganisa izokhula i-oksijini.

Ukulwa nomlilo, uhlelo lwendabuko lwendabuko lusakaza amaconsi amanzi ngaphezulu kwendawo enikeziwe, edonsa ukushisa ukupholisa igumbi. Ngenxa yobukhulu babo obukhulu kanye nendawo emincane, ingxenye eyinhloko yamaconsi ngeke ithole amandla anele okuhwamuka, futhi ngokushesha bawela phansi njengamanzi. Umphumela uba umphumela opholile opholile.

Ngokuphambene, i-High-Water Ater Mist iqukethe amaconsi amancane kakhulu, awela kancane. Amaconsi ama-Water Mist anesimo esikhulu sendawo ehlobene nesisindo sawo futhi, ngesikhathi sokwethuka kwabo kancane ebheke phansi, bamunca amandla amaningi. Inani elikhulu lamanzi lizolandela umugqa we-satuanation futhi lihwaywe, okusho ukuthi i-water mist imunca amandla amaningi asuka endaweni ezungezile bese umlilo.

Yingakho i-High-Water Water Mist ipholisa kahle ilitha lamanzi: kuze kube izikhathi eziyisikhombisa kangcono kunokutholwa ilitha elilodwa lamanzi asetshenziswe ohlelweni lwendabuko lwendabuko.

Ukuqalisa

Isimiso Sokudla Kwamanzi

I-Water Mist ichazwa ku-NFPA 750 njengesifutho samanzi lapho i-DV0.99, ngokusatshalaliswa kwe-volumetric okugcwele okugcwele kwamaconsi amanzi, kungaphansi kwama-microns ayi-1000 ekucindezelweni okuncane okusebenzayo kwe-nozzle yamanzi. Uhlelo lwamanzi inkungu lusebenza ngokucindezela okuphezulu ukuletha amanzi njengenkungu enhle ye-atomised. Le nkampu iguqulwa ngokushesha ibe umusi oshama umlilo futhi ivimbele okwengeziwe umoya-mpilo ukuthi angakufinyeleli. Ngasikhathi sinye, ukuhwamuka kwakha umphumela omkhulu wokupholisa.

Amanzi anezakhiwo ezinhle kakhulu zokumuncwa kokushisa okuthola ama-378 kJ / kg. futhi 2257 kj / kg. Ukuguqukela kuSteam, kanye ne-1700: Ukunwetshwa okungu-1 ngokwenza kanjalo. Ukuze usebenzise lezi zindawo, indawo engaphezulu kwamaconsi yamanzi kumele ilungiswe futhi isikhathi sayo sokuhamba (ngaphambi kokushaya izindawo eziphakeme) kwandiswe. Ngokwenza kanjalo, ukucindezelwa komlilo kwemililo evutha amalangabi kungatholwa ngokuhlanganiswa kwe

1.Ukushisa okushisa kusuka emlilweni nakuwo uphethiloli

2.Ukuncishiswa komoya-mpilo nge-Steam Scopesting eFlame Front Front

3.Ukuvinjwa kokudluliselwa kokushisa okukhanyayo

4.Ukupholisa kwamagesi wokuhlanganisa

Ngomlilo ukuze usinde, kuncike ekubeni khona kwezinto ezintathu 'zonxantathu womlilo': umoya-mpilo, ukushisa kanye nezinto ezivuthayo. Ukususwa kwanoma iyiphi yalezi zinto kuzocima umlilo. Uhlelo lwe-High-Water Fruscient Am Fruing luyaqhubeka. Ihlasela izinto ezimbili zonxantathu womlilo: umoya-mpilo nokushisa.

Amaconsi amancane kakhulu ohlelweni lwamanzi acindezele kakhulu amunca ngokushesha amandla kangangokuba amaconsi aqhakambisa futhi aguqule kusuka emanzini aqonde emthanjeni, ngenxa yendawo ephezulu yendawo ehlobene nobuningi bamanzi. Lokhu kusho ukuthi i-droplet ngayinye izokwanda cishe izikhathi ezingama-1700, lapho isondelana nezinto ezivuthayo, lapho umoya-mpilo kanye nezinsimbi ezivuthayo zizosuswa emlilweni, okusho ukuthi inqubo yokuhlanganisa izokhula i-oksijini.

Ukulwa nomlilo, uhlelo lwendabuko lwendabuko lusakaza amaconsi amanzi ngaphezulu kwendawo enikeziwe, edonsa ukushisa ukupholisa igumbi. Ngenxa yobukhulu babo obukhulu kanye nendawo emincane, ingxenye eyinhloko yamaconsi ngeke ithole amandla anele okuhwamuka, futhi ngokushesha bawela phansi njengamanzi. Umphumela uba umphumela opholile opholile.

Ngokuphambene, i-High-Water Ater Mist iqukethe amaconsi amancane kakhulu, awela kancane. Amaconsi ama-Water Mist anesimo esikhulu sendawo ehlobene nesisindo sawo futhi, ngesikhathi sokwethuka kwabo kancane ebheke phansi, bamunca amandla amaningi. Inani elikhulu lamanzi lizolandela umugqa we-satuanation futhi lihwaywe, okusho ukuthi i-water mist imunca amandla amaningi asuka endaweni ezungezile bese umlilo.

Yingakho i-High-Water Water Mist ipholisa kahle ilitha lamanzi: kuze kube izikhathi eziyisikhombisa kangcono kunokutholwa ilitha elilodwa lamanzi asetshenziswe ohlelweni lwendabuko lwendabuko.

1.3 Isingeniso Sokubhekelwa Amanzi Amanzi Aphakeme

Uhlelo oluphezulu lwe-Water Pressure Amanzi luhlelo oluyingqayizivele lokucisha umlilo. Amanzi aphoqelelwa ngokusebenzisa ama-nozzles amancane ngengcindezi ephezulu kakhulu yokwakha inkungu yamanzi ngokusatshalaliswa kosayizi wokucisha umlilo okusebenzayo kakhulu. Imiphumela yokucishanisa ihlinzeka ngokuvikelwa okulungile ngokupholisa, ngenxa yokutholwa kokushisa, futhi ingenele ngenxa yokwanda kwamanzi cishe ngezikhathi eziyi-1,700 lapho kuhwamuka.

1.3.1 Ingxenye esemqoka

Ama-nozzles aklanywe ngokukhethekile ama-nozzles

Ama-nozzles aphezulu we-Amanzi Amanzi asuselwa kwinqubo yama-nozzles ayingqayizivele amancane. Ngenxa yefomu labo elikhethekile, amanzi azuza ukunyakaza okuqinile okujikelezayo egumbini lokujikeleza kwe-SWIRL futhi aguqulwa ngokushesha abe inkungu yamanzi efakwe emlilweni ngejubane elikhulu. I-angle enkulu yokufafaza kanye nephethini yokufafaza ama-nozzles amancane anika amandla izikhala eziphakeme.

Amaconsi akhiwa kumakhanda ama-nozzle adaliwe kusetshenziswa phakathi kwemigoqo eyi-100-120 yengcindezi.

Ngemuva kochungechunge lwezivivinyo zomlilo ezijulile kanye nokuhlolwa kwemishini nokubonakalayo, ama-nozzles enzelwe ngokukhethekile inkungu yamanzi ephezulu. Zonke izivivinyo zenziwa yi-latheratories ezizimele ukuze kufezeke izimfuno eziqinile zogu lolwandle.

Idizayini yepompo

Ucwaningo olunzulu luholele ekudalweni kwephampu ekhanyayo yezwe eliphakeme kakhulu. Amaphampu amaphampu we-piston ama-axial axist enziwe ngensimbi emelana ne-cororight engapheli. Idizayini eyingqayizivele isebenzisa amanzi njenge-lubricant, okusho ukuthi okusebenzayo okusebenzayo nokubuyisa indawo izinto zokugcoba akudingeki. Iphampu ivikelwe ngamalungelo obunikazi aphesheya futhi isetshenziswa kabanzi ezigabeni eziningi ezahlukahlukene. Amaphampu anikela ngokusebenza kahle kwamandla angama-95% kanye ne-pulsation ephansi kakhulu, ngaleyo ndlela anciphise umsindo.

Ama-valves anobufakazi obukhulu

Ama-valves aphakeme aphezulu enziwa ngensimbi engenasici futhi anobufakazi obukhulu bokugqwala kanye nokungcola okungcolile. Umklamo we-manifold block wenza ama-valves acwebile, awenza kube lula kakhulu ukufaka futhi asebenze.

1.3.Izinzuzo ezi-2 ze-High Pressure Water Mist System

Izinzuzo zohlelo oluphakeme lwezinwele zamanzi lukhulu. Ukulawula / Ukubeka umlilo ngemizuzwana, ngaphandle kokusebenzisa noma yiziphi izithasiselo zamakhemikhali kanye nokusetshenziswa okuncane kwamanzi futhi usondele kulimaze amanzi futhi esebenza kahle esebenza emvelweni, futhi kuphephile ngokuphelele kubantu.

Ukusetshenziswa okuncane kwamanzi

• Ukulimala kwamanzi okulinganiselwe

• Umonakalo omncane emcimbini ongathandeki wokwenza kusebenze ngengozi

• Isidingo esincane sohlelo lwangaphambi kwesenzo

• Inzuzo lapho kunesibopho sokubamba amanzi

• I-reservoir ayitholakali impela

• Ukuvikelwa kwasendaweni kukunikeza ukulwa nomlilo osheshayo

• Isikhathi esiphansi ngenxa yomlilo ophansi kanye nomonakalo wamanzi

• Ubungozi obuncishisiwe bokulahlekelwa amasheya ezimakethe, njengoba ukukhiqizwa kuyakhuphuka ngokushesha futhi kuqhuba futhi

• Kusebenza kahle - futhi nokulwa nemililo kawoyela

• Izikweletu eziphansi zokuhlinzekwa kwamanzi noma izintela

Amapayipi amancane ensimbi angenasici

• Kulula ukuyifaka

• Kulula ukuphatha

• Isondlo samahhala

• Idizayini ekhangayo yokufakwa okulula

• Ikhwalithi ephezulu

• Ukuqina okuphezulu

• Izindleko ezisebenzayo emsebenzini wokusebenza

• Cindezela kufanelekile ukufakwa okusheshayo

• Kulula ukuthola igumbi lamapayipi

• Kulula ukubuyisa kabusha

• Kulula ukugoba

• Kudingeka ukufakwa okumbalwa

Ama-nozzles

• Amandla okupholisa enza ukufakwa kwewindi lengilazi emnyango womlilo

• Isikhala esiphakeme

• Ama-nozzles ambalwa - akhanga ngokwemiklamo

• Ukupholisa kahle

• Ukupholisa iwindi - kunika amandla okuthenga okushibhile

• Isikhathi sokufaka esifushane

• Idizayini yobuhle

1.3.3 Izindinganiso

1. NFPA 750 - Edition 2010

2 Incazelo yesistimu engu-2 nezakhi

2.1 Isingeniso

Uhlelo lwe-HPWM luzoqukatha inani lama-nozzles axhumeke ngamapayipi ensimbi angenasici emthonjeni wamanzi omkhulu (amayunithi wepompo).

2.2 nozzles

Ama-HPWM nozzles angamadivayisi anembile enjiniyela, eklanyelwe ngokuya ngohlelo lokusebenza lesistimu ukuletha ukuphuma kwe-Mist yokukhipha amanzi ngendlela eqinisekisa ukucindezelwa komlilo, ukulawula noma ukucibitheka.

2.3 Isigaba ama-valves - uhlelo lwe-nozzle oluvulekile

Ama-valves wesigaba anikezwa uhlelo lwamanzi okucisha umlilo ukuze ahlukanise izingxenye zomlilo ngamunye.

Ama-Valves weSigaba akhiqizwa ngensimbi engenasici ngakunye kwezingxenye ezizovikelwa ukunikezwa ukufakwa ohlelweni lwamapayipi. I-Valve yeSigaba ivaliwe futhi ivulwa lapho kusebenza uhlelo lokucima umlilo.

Ilungiselelo le-valve lesigaba lingahlelwa ndawonye ndawonye kwi-manifold evamile, bese kufakwa amapayipi ngamanye ama-nozzles afanele. Ama-valves wesigaba nawo angahlinzekwa ngokuvalwa ukuze afakwe ohlelweni lwamapayipi ezindaweni ezifanele.

Ama-valves wesigaba kufanele atholakale ngaphandle kwamakamelo avikelwe uma kungewona amanye amazinga, imithetho kazwelonke noma iziphathimandla.

Isigaba ama-valves sizing asuselwa kwizigaba ngazinye zokwenziwa kwezigaba.

Ama-valves wesigaba sohlelo anikezwa njenge-valve esebenza ngogesi esebenza ngogesi. Ama-valves wesigaba esisebenza ngezimoto ajwayele ukudinga ukusebenzela i-vaf.

I-valve ihlanganiswe ngaphambili kanye nokushintsha kwengcindezi nama-valve e-isolate. Inketho yokuqapha ama-valves okuhlukanisa nawo ayatholakala kanye nezinye izinto ezihlukile.

2.4Futhaumuvo

I-Pump Unit izosebenza ngokujwayelekile isebenza phakathi kwebha eyi-100 nebha ye-140 enamanani okugeleza kwephampu okukodwa ahlabelela ama-100l / min. Izinhlelo zepompo zingasebenzisa amayunithi wepompo owodwa noma amaningi axhumeke ngohlelo oluningi lwenkungu yokuhlangabezana nezidingo zokwakhiwa kohlelo.

2.4.1 Amaphampu kagesi

Lapho uhlelo lusebenza, kuzoqalwa iphampu elilodwa kuphela. Ngezinhlelo ezihlanganisa ipompo engaphezu kweyodwa, amaphampu ayoqalwa ngokulandelana. Uma ukukhuphuka kokugeleza ngenxa yokuvulwa kwama-nozzles amaningi; Amaphampu angeziwe azoqala ngokuzenzakalelayo. Amaphampu amaningi kuphela adingekayo ukugcina ukugeleza kwengcindezi yokugeleza kanye nokusebenza njalo nge-System Design kuzosebenza. Uhlelo oluphakeme lwe-Water Amanzi Iphutha lusasebenza lusebenze kuze kube yilapho abasebenzi abaqeqeshiwe noma i-fire brigade evale uhlelo.

Uphiko lwePup Pump

Iyunithi yePump iyiphakethe elilodwa elihlanganisiwe le-skid elihlanganisiwe elenziwe le mihlangano elandelayo:

| Iyunithi yokuhlunga | Ithangi le-buffer (kuncike ekucindezelweni kwe-inlet kanye nohlobo lwepompo) |

| Ithangi elichichima nokulinganisa kwezinga | Ithange lethangi |

| Buyisela ipayipi (kungahle kuholele ekutholeni) | Inlet manifold |

| Umugqa wokumunca manifold | I-HP Pump Unit (s) |

| Motor kagesi (s) | Ingcindezi manifold |

| Pilot Pump | Iphaneli yokulawula |

2.4.2Iphaneli yePump Unit

Iphaneli yokulawula i-Motor Starter injengezinga elifakwe engxenyeni yepompo.

Ukuhlinzekwa kwamandla okujwayelekile njengokujwayelekile: 3x400V, 50 Hz.

Amaphampu) aqondile emgqeni aqale njengezinga. Qala-Delta ukuqala, ukuqala okuthambile nokuqala kokuguqula imvamisa kunganikezwa njengezinketho uma kuncishiswa ukuqala kwamanje kuyadingeka.

Uma iyunithi lempompo liqukethe ipompo engaphezu kweyodwa, indawo yokuhlala isikhathi sokuhlanganisa kancane kancane kwamaphampu kwethulwe ukuthola okungenani umthwalo wokuqalisa.

Iphaneli yokulawula ine-RAL 7032 Qeda Okujwayelekile ngesilinganiso sokuvikelwa kwe-Ingress se-IP54.

Ukuqala kwamaphampu kutholakala ngale ndlela elandelayo:

Izinhlelo ezomile- kusuka koxhumana naye ongenama-volt-free signal onikezwe kuphaneli yokulawula i-Fire Detection System.

Izinhlelo ezimanzi - kusuka ekwehleni kwengcindezi ohlelweni, kubhekwe yiphaneli yokulawula izimoto yePup Unit.

Uhlelo lwangaphambi kwesenzo - dinga izinkomba ezivela kokubili kwehla lokucindezela komoya ohlelweni kanye noxhumana noxhumana naye ongenama-volt-free signal onikezwe ephaneli lokulawula umlilo.

2.5Imininingwane, amatafula kanye nemidwebo

2.5.1 nozzle

Ukunakekelwa okukhethekile kufanele kuthathwe ukugwema ukuvinjwa lapho kuklama amasistimu we-Whempi ARD, ikakhulukazi lapho usebenzisa ukugeleza okuphansi, ama-nozzles amancanyana aphansi njengoba ukusebenza kwawo kuthinteka kabi ngokuvinjwa. Lokhu kungenxa yokuthi i-flux density itholakala (ngalezi zzzles) ngomoya oyisiyaluyalu ngaphakathi kwekamelo okuvumela inkungu ukuthi ingasatshalaliswe ngaphakathi ngaphakathi kwekamelo njengoba kuvutha ekuvinjelweni nasekudonsa kunokusakaza ngokulinganayo isikhala.

Ubukhulu nebanga lokuvimbela kuncike uhlobo lwe-nozzle. Imininingwane ingatholakala kumashidi wedatha we-nozzle ethile.

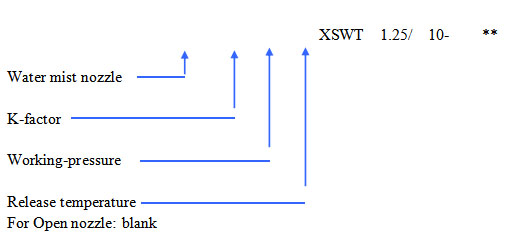

Umkhiwane 2.1 nozzle

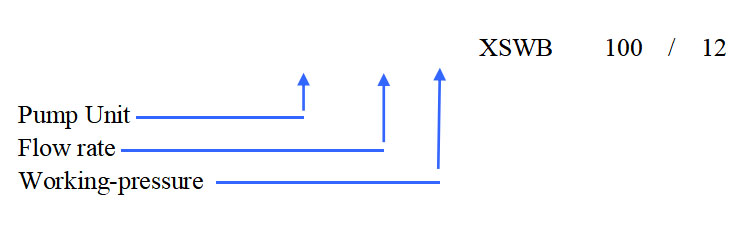

2.5.2 Iyunithi yepompo

| Ukuthayipha | Okukhishwayo l / min | Ubuqhwaga KW | Uphiko lwePup Pump olujwayelekile ngephaneli yokulawula L x w x h mm | -Ngaphansi m | Isisindo seyunithi yepompo kg approussi |

| I-XSWB 100/12 | 100 | 30 | 1960×430×I-1600 | Ø42 | I-1200 |

| I-XSWB 200/12 | -Mashumi | 60 | I-2360×830×I-1600 | Ø42 | 1380 |

| I-XSWB 300/12 | 300 | 90 | I-2360×830×1800 | Ø42 | 1560 |

| I-XSWB 400/12 | 400 | I-120 | I-2760×11×1950 | Ø60 | 1800 |

| I-XSWB 500/12 | 500 | I-150 | I-2760×11×1950 | Ø60 | 1980 |

| I-XSWB 600/12 | I-600 | Umfana no-180 | I-3160×Oku-12×1950 | Ø60 | 2160 |

| I-XSWB 700/12 | I-700 | 210 | I-3160×Oku-12×1950 | Ø60 | 2340 |

Amandla: 3 x 400vac 50hz 1480 RPM.

I-Fig 2.2 Pump Unit

2.5.3 Imihlangano Ejwayelekile ye-Valve

Imihlangano ye-valve ejwayelekile ikhonjiswa ngaphansi kwe-Fig 3.3.

Lo mhlangano we-valve unconyelwe amasistimu we-multi-punts odliwe kumanzi afanayo. Lokhu kucushwa kuzovumela ezinye izigaba ukuthi zihlale zisebenza ngenkathi kulungiswa i-ONE.

I-FIK 2.3 - Umhlangano we-Valve ojwayelekile we-Valve - Uhlelo Olomile Pipe olune-Open Nozzles