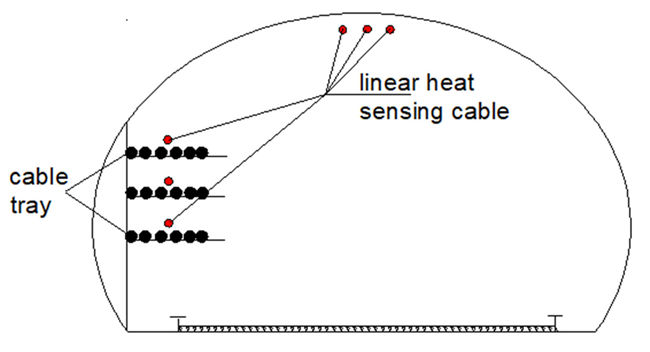

1. I-Cable Tray, umhubhe wekhebula, umsele wekhebula, umlandeli wekhebula, nezinye izindawo ezingamakhekhe '

Ngokutholwa komlilo endaweni yekhebula, i-LHD ingafakwa ku-S-HAMUS noma i-Sine Wave Ukubeka ukubekwa (lapho ikhebula lamandla lingadingi ukushintshwa) noma ukumiswa kwamandla okuvuselelwa kokumiswa komhlaba (lapho ikhebula lamandla lidinga ukushintshwa noma ligcinwe).

Ukuze uqinisekise ukuzwela nokusebenza kahle kokutholwa komlilo, ukuphakama okuqondile phakathi kwe-LHD nobuso bekhebula elivikelwe akufanele kube kukhulu kune-300 mm, kwathi kunconywa u-150 mm mm.

Ukuze uqinisekise ukuthembeka kokutholwa komlilo, i-LHD kufanele ihlelwe maphakathi ne-tray yekhebula evikelekile noma ubakaki lapho ububanzi be-tray yekhebula noma i-bracket bungaphezulu kwe-600mm, futhi i-LHD yohlobo lwe-2-line kufanele ifakwe.

Ubude bokutholwa kokushisa okuqondile kwe-LHD kunqunywa yifomula elandelayo:

Ubude bomtshina = ubude be-tray × the relply contor

| Ububanzi be-tray ikhebula | Isiphindaphinda futhi |

| 1.2 | 1.73 |

| 0.9 | 1.47 |

| 0.6 | I-1.24 |

| 0.5 | 1.17 |

| 0.4 | 1.12 |

2. Imishini yokusatshalaliswa kwamandla

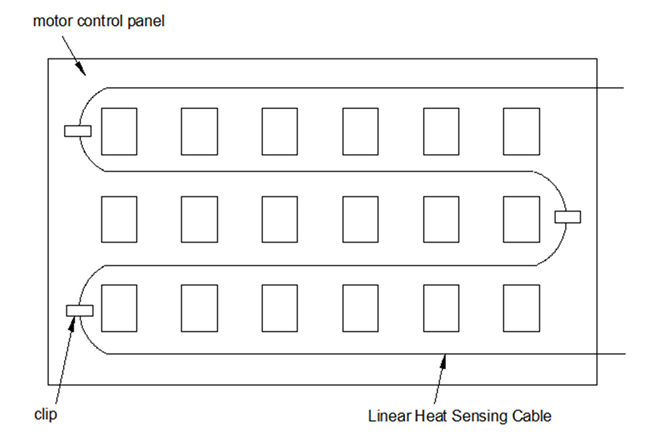

Ukuthatha umtshina wokushisa oqondile we-LHD efakwe kwiphaneli yokulawula imoto njengesibonelo. Ngenxa yocingo oluphephile noluthembekile lwe-wire nokubopha, lonke idivaysi ivikelwe. Eminye imishini kagesi, efana ne-Transformer, i-Knife switch, i-Resign Bar of Main Distribung device, ingathatha indlela efanayo lapho izinga lokushisa elikhona lingadluli ekushiseni kokusebenza okuvumelekile kwe-linear lokushisa umtshina we-LHD.

Ngokutholwa komlilo endaweni evikelwe, i-LHD ingafakwa ku-S-HAMSOP noma i-Sine Wave Xhumana nomtshina ihlelwe ngokulungiswa okukhethekile ukugwema ukulimala kwemishini okubangelwa ukucindezelwa. Imodi yokufaka ikhonjiswa kwisibalo

3. Ibhande elidluliselwe

Ibhande elihambisayo liqhutshwa ibhande lemoto eBelt Roller Movement to Transports. Ibhande roller kufanele likwazi ukujikeleza ngokukhululeka emgodini olungisiwe ngaphansi kwezimo ezijwayelekile. Kodwa-ke, uma iBelt Roller yehluleka ukujikeleza ngokukhululeka, ukungqubuzana kuzokwenzeka phakathi kwebhande nebhande roller. Uma kungatholakali ngesikhathi, izinga lokushisa eliphakeme elikhiqizwe ukuxabana isikhathi eside lizokwenza ukuba ibhande nezindatshana ezithuthe zishise futhi zikhaxe.

Ngaphezu kwalokho, uma ibhande lokuhambisa lidlulisela amalahle nezinye izinto, ngoba uthuli lwamalahle lunengozi yokuqhuma, kuyadingeka futhi ukukhetha izinga elihambisanayo le-Explosive-Proof Linear Heat Detector Ep-LHD

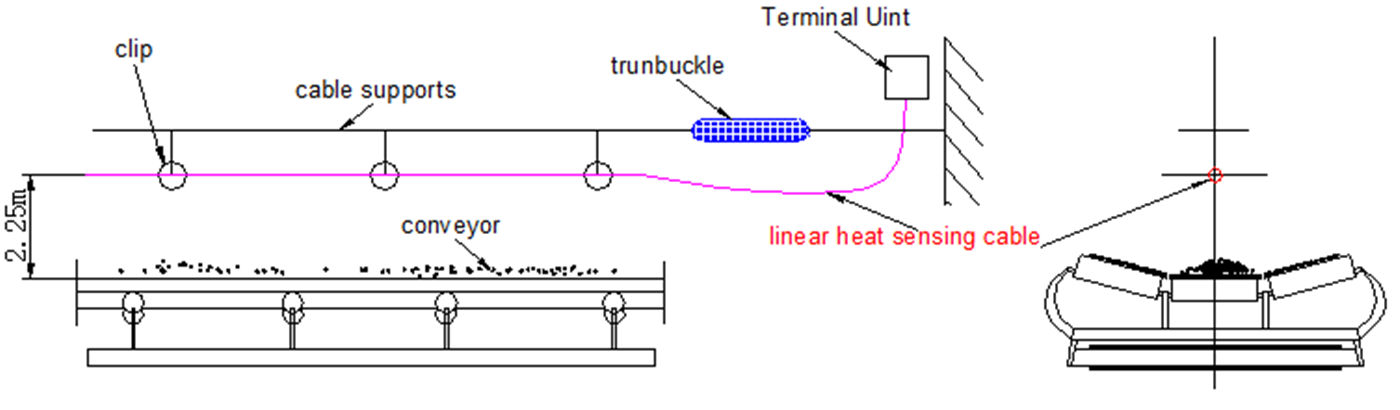

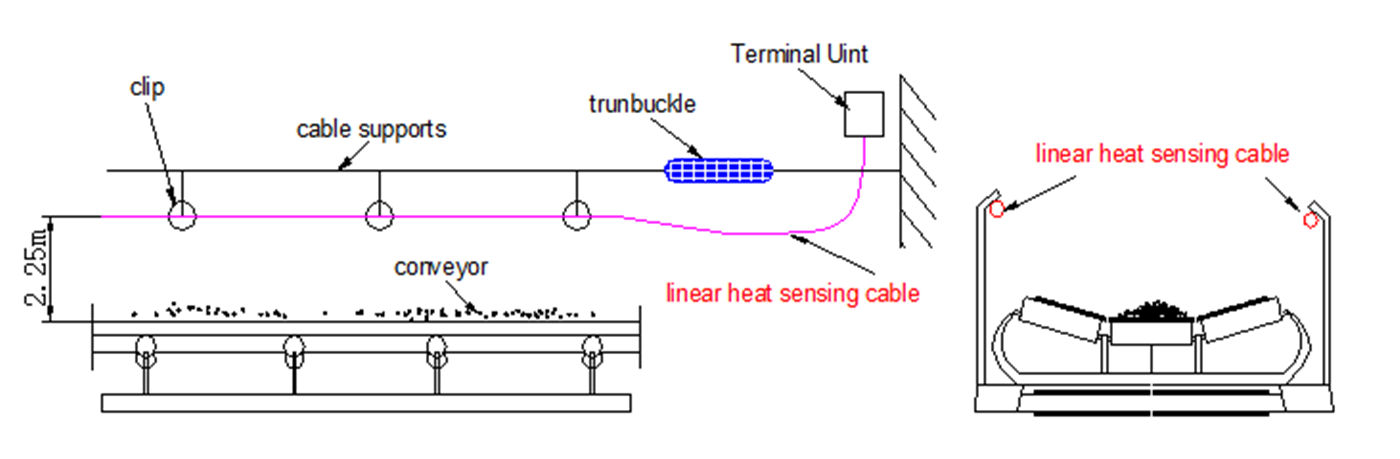

I-Converor Belt: Design 1

Ngaphansi kwesimo sokuthi ububanzi bebhande lokuhambisa angeqi kwe-0.4m, ikhebula le-LHD ngobude obufanayo nebhande lokuhambisa lisetshenziselwa ukuvikela. Ikhebula le-LHD lizolungiswa ngqo kwisengezo esingadluli ku-2.25m ngaphezulu kwesikhungo sebhande lokuhambisa. Isengezo singaba umugqa wokumiswa, noma ngosizo lwezinto ezikhona esizeni. Umsebenzi wokumiswa kwentambo ukuhlinzeka ukwesekwa. I-Eye Bolt isetshenziselwa ukulungisa ucingo lokumiswa njalo nge-75m.

Ukuze uvikele ikhebula le-LHD ekuweni phansi, i-fastener kufanele isetshenziselwe ukubopha ikhebula le-LHD kanye nocingo ukumiswa njalo nge-4m ~ 5m. Izinto zocingo ukumiswa kufanele zibe Φ 2 Insimbi engagqwali yensimbi, futhi ubude obubodwa akufanele bube ngaphezu kwe-150m (i-galvanized yensimbi ingasetshenziselwa ukuwufaka esikhundleni lapho izimo zingatholakali). Indlela yokufaka ikhonjiswa kwisibalo.

Convoyer Belt: Design 2

Lapho ububanzi be-conveveror bebhande budlula u-0.4 m, faka ikhebula le-LHD nhlangothi zombili eduze kwebhande lokuhambisa. Intambo ye-LHD ingaxhunyaniswa ebholeni elithwele ukushisa kwepuleti ukuthola ukushisa ngokweqile ngenxa yokufaka izingxabano nokuqongelelwa kwamalahle adonsayo. Umgomo ojwayelekile wokufakwa kanye nokufakwa kususelwa ezimweni zesayithi ngaphandle kokuthinta ukusebenza okujwayelekile nokulungiswa. Uma kunesidingo, uma isici sengozi yomlilo sikhulu, umtshina wokushisa oqondile we-LHD anganamathiselwa kuzo zombili izinhlangothi nangaphezulu kwebhande lokuhambisa. Indlela yokufaka ikhonjiswa kwisibalo

4. Imigudu

Isicelo esijwayelekile emgwaqweni omkhulu kanye nezitimela ukuzolungisa ikhebula le-LHD ngqo ngaphezulu komhubhe, futhi indlela yokubeka iyafana naleso esitolo; Ikhebula le-LHD lingafakwa futhi ku-tray yekhebula negumbi lemishini emhubheni, kanye nendlela yokubeka kubhekisele engxenyeni yekhebula le-LHD elibeka ugqoko wekhebula.

5. I-Rail Transit

Ukusebenza okuphephile kokuhamba kwezitimela zasemadolobheni kubandakanya imishini eminingi, ikakhulukazi amaphutha okusebenza ngomshini kanye nogesi kanye nomjikelezo ofushane kagesi kuyisici esibalulekile esibangela umlilo, ikakhulukazi umlilo wentambo uyimbangela enkulu. Ukuze uthole umlilo ekuseni kakhulu ekuqaleni komlilo bese unquma indawo yomlilo, kuyadingeka ukuze uhlele kahle umtshina womlilo bese uhlukanisa igumbi lomlilo. I-Linear Heat Detector LHD ilungele ukuthola umlilo wekhebula kutilongo lesitimela. Ngokwehlukaniswa kwegumbi lomlilo, sicela ubheke imininingwane efanelekile.

I-linear Heat Detector LHD ihlelwe phezulu noma ohlangothini lwethrekhi bese ibekwa eceleni kwethrekhi. Lapho kunohlobo lwekhebula lwamandla ethrekhi, ukuze kuvikeleke ngentambo yamandla, i-linear Heat Detector LHD ingafakwa ngo-Sine Wave oxhumana naye, okufanayo nalokho okusetshenzisiwe ku-tray yekhebula.

I-LHD ihlelwe ku-ukumiswa okufakwe ku-ukufakwa kusengaphambili ngokuya ngomugqa wokubeka i-LHD, futhi ibanga phakathi kokumiswa ngakunye kokumiswa kuvame ukuba ngu-1 m-1.5 m.

6. Amapulazi eTank for Amafutha, igesi, kanye ne-petrochemical

Amathangi e-petrochemical, amathangi kawoyela negesi ikakhulukazi ahlelwe uthango ophahleni lwethangi elintantayo. I-LHD ingafakwa ngokumiswa noma ukuxhumana ngqo lapho kufakwa ethangini elilungisiwe.

Amathangi ngokuvamile amathangi amakhulu anesakhiwo esiyinkimbinkimbi. Izibalo ikakhulukazi zokwethula ukufakwa kwe-LHD ngamathangi ophahla ontantayo. Imvamisa yomlilo yendandatho yokubopha yethanga lokuntanta liphezulu.

Uma uphawu lungaqinile, ukugcwala kwamafutha negesi kuzoba ohlangothini oluphezulu. Lapho izinga lokushisa elizungezile seliphezulu kakhulu, kungenzeka libangele umlilo noma ukuqhuma. Ngakho-ke, ukugcwala kwendandatho yokubopha uphawu lethangi elintantayo liyingxenye ebalulekile yokuqapha umlilo. Ikhebula le-LHD lifakwe ezungeze indandatho ye-roof entantayo entantayo futhi ilungiswe ngokulungiswa okukhethekile.

7. Isicelo kwezinye izindawo

I-Linear Heat Detector LHD ingafakwa kwi-Industrial Warehouse, i-workshop kanye nezinye izindawo. Ngokusho kwezimpawu zento evikelwe, i-LHD ingafakwa ophahleni noma odongeni lwesakhiwo.

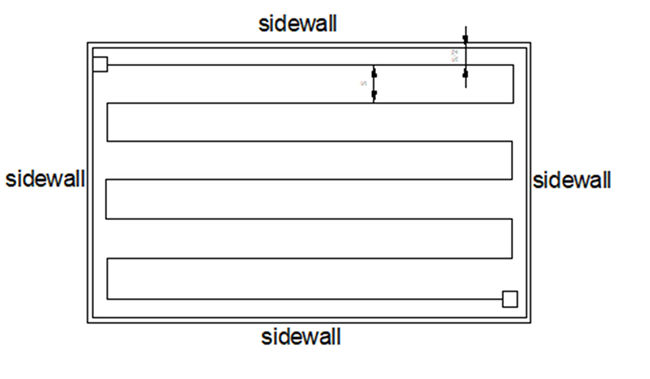

Njengoba indawo yokugcina impahla kanye nomhlangano wokufundisa unophahla oluyisicaba noma uphahla olubekiwe, indlela yokufaka ye-Linear Heat Detector LHD kulezi zakhiwo ezimbili ezahlukene zokwakheka ihlukile, echazwa ngokwahlukana ngezansi.

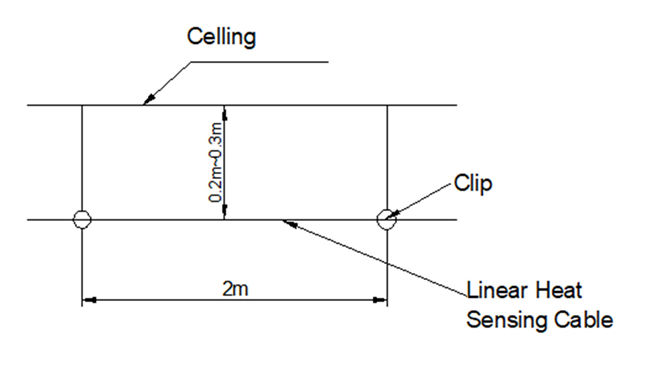

(1) Ukufakwa kwe-Linear Heat Detector LHD esakhiweni sophahla sophahla

Lolu hlobo lomtshina oqondile luvame ukulungiswa ophahleni nge-LHD Wire ebangeni le-0.2m. I-Linear Temperity Detector LHD kufanele ibekwe ngendlela yokumiswa okuhambisanayo, futhi isikhala sekhebula sekhebula le-LHD selichazwe phambilini. Ibanga phakathi kwekhebula nomhlabathi kufanele kube ngu-3m, hhayi ngaphezu kwe-9m. Lapho ibanga phakathi kwekhebula nomhlabathi kungaphezu kwama-3m, ibanga phakathi kwentambo nomhlabathi kuzoncishiswa ngokuya ngalesi simo. Uma izimo zokufaka zivuma, kuphakanyiswa ukuthi umtshina wokushisa oqondile we-LHD kufanele ufakwe eduze kwendawo evuthayo, enenzuzo yokuthi umtshina angaphendula ngokushesha ngomlilo.

Lapho isetshenziswa eshalofini lama-warehouse, ikhebula lokuzwakala lokushisa lingafakwa ngaphansi kophahla futhi luhlelwe eceleni komugqa wesikhungo seshalofini, noma unamathiselwe ngepayipi lesistimu yokufafaza. Ngasikhathi sinye, ikhebula le-LHD lingalungiswa endaweni yokufaka umoya omncane. Lapho kunempahla eyingozi eshalofini, ikhebula le-LHD kufanele lifakwe eshalofini ngalinye, kepha ukusebenza okujwayelekile kweshelufu akufanele kuthinteke, ukuze kugwenywe ukulimaza ikhebula le-LHD ngokugcina nokugcina izimpahla. Ukuze ubone umlilo osezingeni eliphansi kangcono, kuyadingeka ukwengeza ungqimba wekhebula lokushisa elibucayi endaweni ephakeme eshalofini elinokuphakama okungaphezulu kwe-4,5m. Uma kukhona uhlelo lokufafaza, lungahlanganiswa nongqimba lwe-Sprinkler.

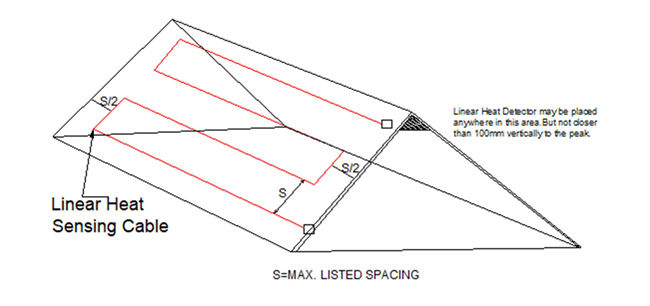

(2) Ukufakwa kwe-Linear Heat Detector LHD ekwakhiweni kophahla ophahleni

Lapho elele endaweni enjalo, leli khebula elizalo ibanga lokushisa lekhebula lokushisa lingabhekisela ebangeni elibekelwe amakhebula lentambo yekhebula lokuzwakala egumbini eliphansi.

Bona umdwebo we-schematic.

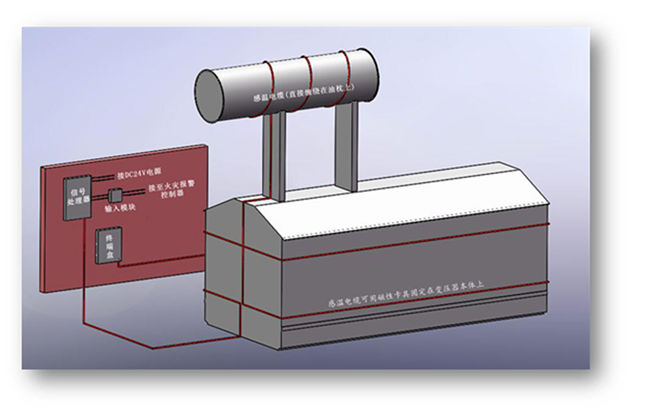

(3) Ukufakwa ku-transformer egxile uwoyela

I-Linear Heat Detector LHD ikakhulukazi ivikela umzimba we-transformer kanye nomlondolozi.

Ikhebula le-linear Heat Detector LHD lingafakwa kwintambo yensimbi yensimbi enobubanzi obungu-6 mm azungeze umzimba we-transformer. Inani lamakhoyili anukayo lizimisele ngokuya ngokuphakama kwe-transformer, futhi ukuhanjiswa ku-conservator kungabi ngaphansi kwamakhoyili ama-2; Ukuphakama okuphezulu kwekhoyili ephakeme kucishe kube ngu-600 mm ngaphansi kwesembozo esiphezulu sethangi lamafutha, kanti ikhebula lokuzwakala le-LH-150 mm lisuselwa ku-sholl noma i-terminall, futhi iyunithi lokulawula le-lhd lingatholakala endaweni ephuma ngaphandle kodonga ngaphandle kwe-transformer, eliphakeme ukusuka emhlabathini.